reEvolution

Diffusion Denuders OLD

ENVINT GAS08/16 Gas/Aerosol Manual Sampler

The Gas/aerosol manual sampler is a device intended for the selective sampling of gases and aerosol present in the atmospheric environment. The term manual makes reference to the need of analysing the samples after the sampling step. Sampling is completely automatic and does not need any kind of external intervention. Basically the instrumentation offered in the bid consists of:

- Sampler accommodating 6 sampling lines which can be arranged in different configuration

- Denuders and filter packs for the collection of gas and aerosol species

- Sampling pump

- Control electronics

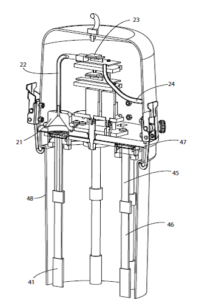

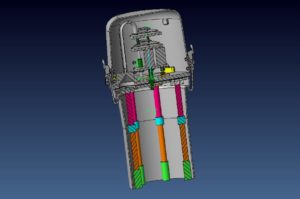

Sampler consist of a container to accommodate a number of denuder lines (typically from 6 to 8). Lines are accommodated in sampling positions which are selected according to the time sequence specified in the programming operations. A plastic shield (48) is used to operate the system in open sites. The figure shows a sampling train made up with two denuders (45 and 46) and a filter pack (47). As shown later on, denuders collect reactive gases, while filter pack includes a series of filters for particulate components. Each line is screwed into the sampling unit from which is removed after sampling for the following chemical analysis. Before and after sampling the denuders are protected by passive contamination by external air by a Teflon ball valve (41) which opens when the sampling starts.

Programming of the sampler is carried out by means of a Tablet working in Android OS. The user may program:

- sequence of sampling,

- time of sampling

- Flow rate

through a Wi-Fi connection.

The system records:- Sequence of sampling

- Start and end time of each sampled channel

- Ambient temperature, pressure and relative

- Flow rate (at standard T and P)

- Pressure drop on filter pack

- Volume of sampled air

All information are stored in the internal memory of the sampler (23) and transmitted via Wi-Fi to users during visit at the site.

The system is programmed in order to continuously check the electronic and pneumatic (22, 24) part of the sampler. According to operating values, the system may generate the following alarm situations:

- Pressure drop too high for maintaining the selected flow rate (Filter clogging)

- Pressure drop too low (filter breaking)

- External Power fail and restart times.

The sampler operates at 220VAC mainly used for the pump. An internal battery is used to maintain active the electronic circuit and the memory for a long time (at least 15 days)

Denuders and filter packDenuders are annular denuders of size 150×16.2 mm (annular space: 16,2-15 mm) made of glass specifically developed for the collection of gas and aerosols. As is known, when air flows through an annual denuders coated with a selective specific chemical species, gas molecules diffuse on the walls and are removed from the airstream. Aerosols proceed unaffected and are collected on the filter pack. For instance if a denuder is coated with an acid (i.e. Phosphorous acid) ammonia will be efficiently collected. If the coating is an alkaline species (Sodium Carbonate), then acidic gases (i.e, SO2) will be collected. Since the denuder may be assembled in series, selective removal of different gases may be achieved. After sampling, the denuder walls can be extracted with water and analysed by ion chromatography (IC) and the concentration of reactive gases may be obtained.

The filter pack is made up of the following components:

- Impactor for selecting the fraction (Typically PM2,5)

- A front Teflon filter for the collection of inert particles

- A Nylon filter for the collection of acids released by particulate collected on the front Teflon filter

- A paper filter impregnated with phosphorous acid to collect ammonia released by the front Teflon filter

The evaporation of volatile ammonium salts from the fine particles collected on the front Teflon filter is due to fluctuations in temperature and relative humidity and/or pressure drop across this filter, which perturb the gas-particle equilibrium. Total concentrations of ammonium salts in PM2.5 are estimated as the sum of the measurements both on the Teflon filter for non-volatile fine particulate species (unevolved particulate

species) and on the back-up filters for volatile fine particulate species (evolved particulate species):

[NO3−]evolved =[NO3−]N (1) [Cl−]evolved =[Cl−]N (2) [NH4+]evolved =[NH4+]N+[NH4+]PA (3) [NO3−]unevolved =[NO3−]T (4) [Cl−]unevolved =[Cl−]T (5) [NH4+]unevolved =[NH4+]T (6) [NO3−]fine =[NO3−]unevolved+[NO3−]evolved (7) [Cl−]fine =[Cl−]unevolved+[Cl−]evolved (8) [NH4+]fine =[NH4+]unevolved+[NH4+]evolved (9) [SO4-2]fine =[SO4-2]T (10)where terms N, PA and T stand for the Nylon filter, phosphorous acid coated paper filter and Teflon filter, respectively. The fine particulate SO4−2 is not volatile; therefore, its concentration was taken as that on the Teflon filter only. In conclusion, the system allows the determination of many species related to fine particle formation.

It is worth stressing that the described sampling line is just related to the measurement of several species of significance for inorganic secondary pollution. However, the system can be made more simple and adapted for the measurement of selected species, For instance, by using one denuder and one Teflon filter, it is possible to measure simultaneously the concentration of sulphur dioxide in gas phase and of sulphates in particulate matter. Some example of additional applications is given below.

| Configuration of sampling line |

Measured species |

|

| Denuders | Filter Pack | |

| 1 Alkaline coating (na2CO3) | 1 Nylon | SO2(gas); SO4 (part)

|

| 1 Acid Coating (Citric or Phsphorous Acid) | 1 H3PO3! paper impregnated | NH3(gas); NH4+ (part) |

| 1 Alkaline Carbon | 1 Nylon | NO2(Gas)+NO3.(part) |

| 1 Nacl | 1 Nylon | HNO3(gas)+NO3-(part) |

| 1 NaCl + 1 Akaline Coating | 1Nyllon | HNO3(gas); HNO2 (gas); NO3.(part) |

Sampling pump is a sealed membrane pump able to deliver up to 10 l/min on filter pack at a backpressure compatible with the filters in line. Flow rate measurement is carried out in a very precise way by measuring the air pressure drop across a laminar flow element and recording the temperature. By recording the external temperature it is possible to evaluate the standard volume collected each sampling step as well as the actual volume since the sampler also measure the atmospheric pressure. External temperature and relative humidity are continuously controlled by the system and data can be recovered via Wi-Fi. Since the instrument accepts analog and digital external data, it is possible to activate individual channels according to the status of external devices.

Start and stop on the pump is controlled by the electronics of the system according to the type of programming set by the user and according to external inputs.

Control electronicsControl electric is built around a microprocessor which monitor all variables which may alter the response of the sampling system. Program is introduced in the system through a tablet with Android operating system. Transmission between the electronics is provided by Wi-Fi activated by the user. The electronic unit accepts external analog and digital data which are recorded, stored and used for conditional sampling into the appropriate sampling line. This makes the flexibility of the sampler at very high level since it can operate up to 8 different sampling lines according to external and internal (timing) input.

Such flexibility allow conditional sampling according to, for example,:- time of the day (Daytime and/or night-time measurements)

- wind speed and direction for source apportionment

- exceedance of concentration limits for other pollutants

- traffic conditions in urban areas

- abnormal emissions of toxic species from polluting sources

- Number of sampling lines: 8

- Channel activation: Electro-valves

- Type of samplers:

- Impactors for PM10, PM2,5, PM10

- Membrane filters 37 mm standard (47mm optional)

- Traps for VOC sampling

- Denuder/filter pack lines

- Impregnated filters

- Sampling pumps: 2-10 L/min (1-5 L/min optional)

- Data transmission: Locally via Wi-Fi

- Programming: Via Tablet (Android OS)

- Automatic restart on power fail

- Evaluation of chemical composition of particulate matter

- Mass concentration measurements of PM2,5 and PM10.

- Sequential or conditional sampling to external inputs.

- Simultaneous measurement of PM fractions and gas/aerosol concentration by sampling time distribution (eg, 10 minutes each sampling line).

- Urban and traffic pollution

- Indoor pollution

- Industrial pollution

- Pollution in working sites

- Environmental impact assessment

- Air pollution alerts ad emergencies

- Source apportionment studies